Thermal label printing has revolutionized the labeling industry with its versatile capabilities. This technology relies on the application of thermal energy to a special type of paper, known as thermal paper. When heated, the chemical compounds within the paper undergo a change in color, creating a permanent image. DirectThermographic printing involves passing the print head directly over the thermal paper, while Indirect Thermal printing utilizes a ribbon that melts onto the label surface with the application of heat. This varied range of options allows for customization based on specific labeling requirements.

- Advantages of thermal label printing include its speed, simplicity, and low operating costs.

- Thermal labels are suitable for a variety of applications, including shipping labels, product identification, receipts, and more.

- Furthermore, the high quality and durability of thermal prints make them suitable for both indoor and outdoor use.

Thermal label printing continues to evolve with advancements in print head technology and ribbon materials. This constant development ensures that thermal label printing remains a efficient solution for businesses across diverse industries.

Optimizing Thermal Label Performance

Thermal label performance can be influenced by a variety of factors. To obtain optimal results, it's crucial to analyze termal etiket several key aspects.

One important factor is the standard of the thermal label material itself. Labels made from high-quality materials will deliver a clearer and more durable print. Additionally, the setting used during printing can significantly affect the quality of the label.

It's important to establish the optimal temperature setting for your unique printer and label material. Finally, proper handling and storage of thermal labels are essential for maintaining their performance over time. Storing labels in a cool, dry place away from direct sunlight can help to avoid damage and ensure long-lasting results.

Understanding Thermal Transfer Ink Types

Thermal transfer printing relies a specialized type of ink known as thermal transfer ink. This unique kind of ink is designed to move onto a variety of surfaces when heated by a thermal printhead. There are several common types of thermal transfer inks, each optimized for particular applications and substances.

- A prominent type is wax-based ink, known for its longevity and affordability. It's often used in applications like labeling and barcode printing.

- Another popular type is resin ink, which provides a greater degree of detail. It's commonly used in applications requiring detailed graphics.

- Lastly, there are hybrid inks that blend properties of different ink types, providing a adaptable solution for multiple printing needs.

Understanding the characteristics of each thermal transfer ink type is vital for identifying the right ink for your specific printing requirements and achieving optimal print quality.

Applications of Thermal Labels in Industry

Thermal labels utilize a straightforward and powerful method for labeling various items within industrial settings. Manufacturing sectors across diverse fields, such as food processing, depend on thermal labels for their robustness. These labels offer a reliable solution for recording products, inventory, and shipments throughout the logistics network.

- Uses

- Advantages

- Variations

Formulating Effective Thermal Labels for Visibility

Thermal labels present a effective method for identifying and tracking products. However, to ensure optimal visibility, these labels must be strategically designed. A few essential factors determine the effectiveness of thermal labels, including the choice of materials, inscription technology, and overall label layout.

Opting for the proper material is essential to withstanding the demands of various situations. For situation, labels intended for harsh temperatures must be formulated from materials that retain their legibility even in adverse conditions.

Additionally, the printing process used to manufacture thermal labels significantly impacts their visibility. Thermal printers employ heat-sensitive toners that imprint onto the label material, creating a permanent image. The clarity of the printing method significantly affects the definition of the printed text and graphics.

Challenges and Solutions in Thermal Label Printing

Thermal label printing offers a versatile method for producing high-quality labels, but it encounters several challenges. One common issue is ribbon usage, which can impact overall cost efficiency. Another challenge is ensuring proper label sticking to various surfaces. Furthermore, achieving clear print quality can be challenging depending on the labeling equipment and the type of thermal stock used.

- Fortunately, there are numerous solutions available to overcome these hurdles.

- For instance, utilizing high-density thermal devices can help reduce ribbon consumption.

- Choosing the appropriate adhesive type and applying it correctly is crucial for achieving strong label adhesion.

- Regularly maintaining the thermal printer can help optimize print quality.

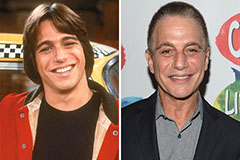

Tony Danza Then & Now!

Tony Danza Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Kerri Strug Then & Now!

Kerri Strug Then & Now!